CNC Machining Explained: A Beginner’s Guide

Introduction to CNC Machines

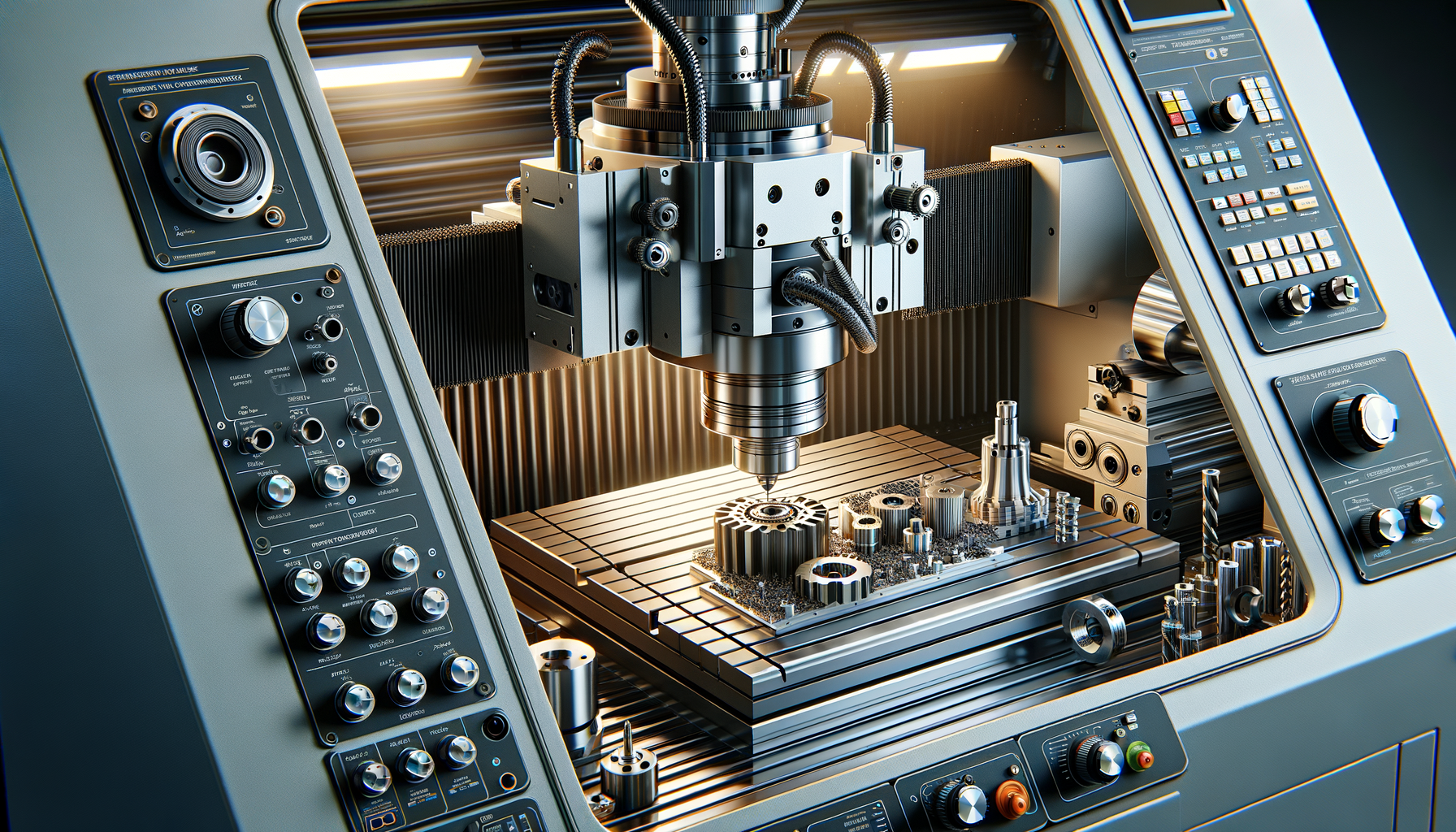

CNC machines, or Computer Numerical Control machines, are automated tools that play a significant role in modern manufacturing industries. These machines are designed to carry out precise cutting, shaping, and drilling tasks with minimal human intervention. The importance of CNC machines lies in their ability to produce intricate parts with high accuracy and repeatability, making them indispensable in sectors such as aerospace, automotive, and electronics manufacturing.

The evolution of CNC technology has transformed traditional manufacturing processes, enhancing productivity and reducing the likelihood of human error. By automating complex tasks, CNC machines help manufacturers meet high-quality standards while optimizing production times. This article delves into the workings of CNC machines, their applications, and the benefits they offer to various industries.

How CNC Machines Work

At the heart of CNC machines is a computer that controls the movement and operation of machine tools. The process begins with a design created in CAD (Computer-Aided Design) software, which is then converted into a series of commands using CAM (Computer-Aided Manufacturing) software. These commands, often referred to as G-code, dictate the movements and actions of the CNC machine.

The machine interprets these commands to precisely control its tools, such as drills, lathes, or mills. The accuracy of CNC machines is achieved through the use of high-precision motors and sensors that ensure each movement is executed with precision. This level of control allows for the creation of complex geometries and intricate details that would be challenging to achieve manually.

In addition to their precision, CNC machines offer versatility. They can be programmed to perform a wide range of operations, from simple cuts to complex 3D shaping. This flexibility makes them suitable for producing a variety of components across different industries.

Applications of CNC Machines

CNC machines are utilized in numerous industries due to their ability to produce high-quality parts efficiently. In the aerospace industry, for instance, CNC machines are used to manufacture critical components such as turbine blades and structural parts. The precision and reliability of CNC machining ensure that these components meet stringent safety and performance standards.

In the automotive sector, CNC machines play a crucial role in producing engine parts, transmission components, and other intricate parts that require high precision. The ability to produce parts with consistent quality helps automotive manufacturers maintain the performance and reliability of their vehicles.

The electronics industry also benefits from CNC machining, particularly in the production of circuit boards and enclosures. The precision of CNC machines ensures that electronic components fit perfectly, reducing the risk of malfunctions.

Advantages of CNC Machining

CNC machining offers several advantages over traditional manufacturing methods. One of the primary benefits is its ability to produce parts with exceptional accuracy and consistency. This precision reduces the need for manual adjustments and rework, saving time and resources.

Another advantage is the efficiency of CNC machines. They can operate continuously with minimal supervision, allowing manufacturers to maximize productivity. This capability is particularly beneficial in high-volume production environments where downtime can be costly.

CNC machines also offer flexibility in production. With the ability to quickly reprogram machines for different tasks, manufacturers can adapt to changing demands and produce custom parts with ease. This adaptability makes CNC machining a valuable asset in industries where innovation and customization are key.

Future Trends in CNC Machining

The field of CNC machining continues to evolve with advancements in technology. One emerging trend is the integration of artificial intelligence and machine learning, which can enhance the capabilities of CNC machines by optimizing tool paths and predicting maintenance needs. This integration could lead to even greater efficiency and reduced operating costs.

Another trend is the development of hybrid machines that combine CNC machining with additive manufacturing techniques. These machines offer the ability to produce complex parts with both subtractive and additive processes, expanding the possibilities for design and production.

As industries continue to demand higher precision and efficiency, CNC machining is likely to play an increasingly important role in manufacturing. By staying at the forefront of technological advancements, CNC machines will continue to drive innovation and productivity across various sectors.