Hydraulic Press Machines: How They Work and What to Consider Before Use

Introduction to Hydraulic Press Machines

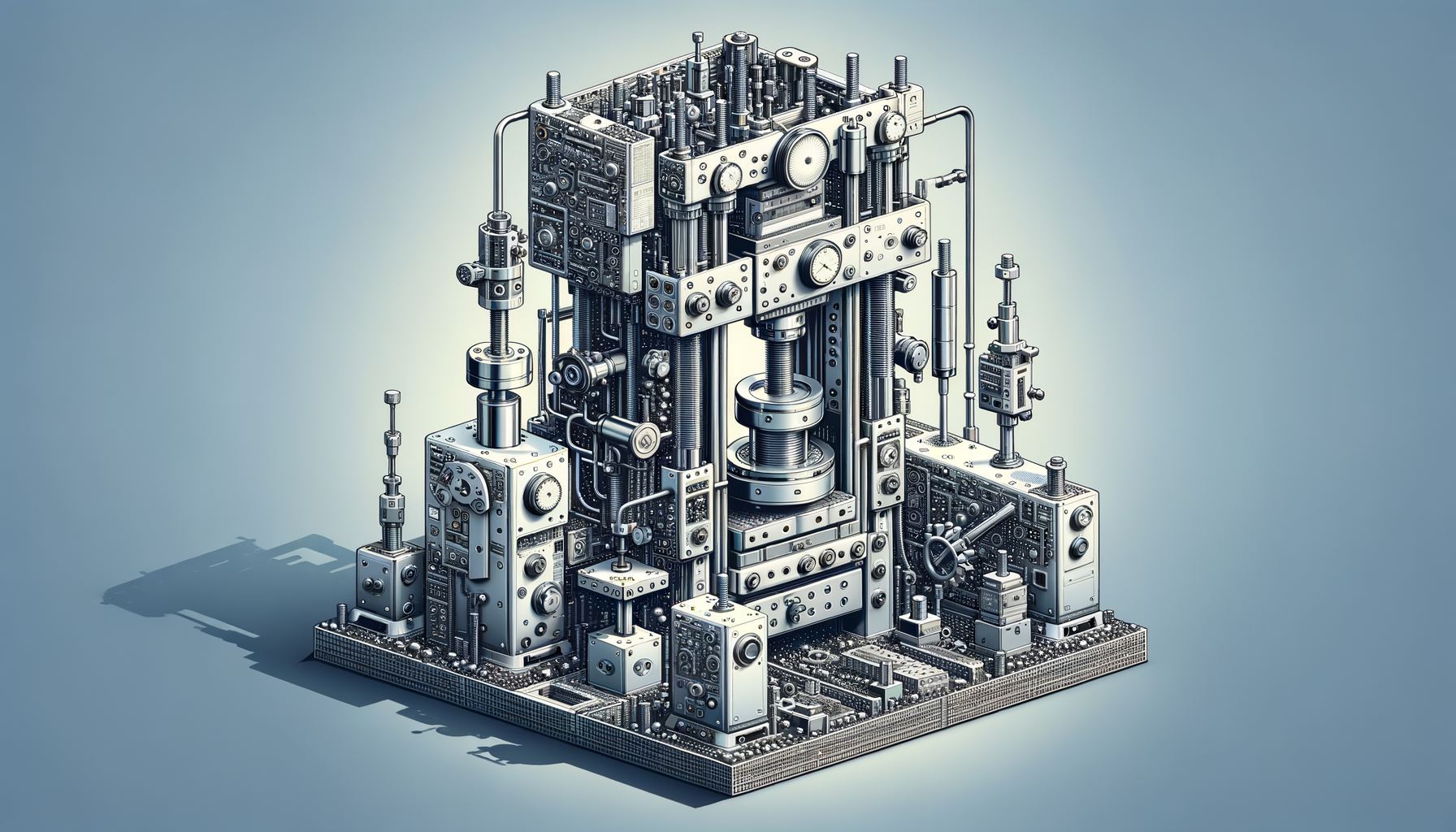

Hydraulic press machines are an integral part of modern manufacturing and industrial processes. These machines utilize fluid pressure to exert a substantial force on a material, making them indispensable for tasks such as shaping, compressing, or cutting. Their application ranges from automotive manufacturing to the creation of intricate metal components, showcasing their versatility and importance in industrial settings. Understanding the mechanics and benefits of hydraulic press machines is essential for anyone involved in manufacturing or industrial processes, ensuring safe and efficient use.

The Mechanics of Hydraulic Press Machines

At the heart of a hydraulic press machine is Pascal’s Law, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This principle allows hydraulic presses to generate immense force with relatively little input energy. The typical hydraulic press consists of a hydraulic cylinder, a piston, and a pump. When the pump pushes hydraulic fluid into the cylinder, it moves the piston, which in turn applies force to the material being processed.

These machines are known for their precision and control, making them suitable for applications requiring consistent force. Key components such as the hydraulic fluid, pump, and seals must be maintained to ensure the machine’s efficiency and longevity. Regular inspection and maintenance can prevent leaks and ensure that the hydraulic system operates smoothly.

Applications and Benefits of Hydraulic Press Machines

Hydraulic press machines are used in a wide array of industries due to their versatility and efficiency. Some of the common applications include:

- Automotive industry: Used for manufacturing car parts such as body panels and chassis components.

- Metalworking: Essential for cutting, bending, and shaping metal sheets.

- Plastic industry: Utilized in molding processes to create plastic parts.

- Waste management: Compacts waste materials for easier handling and recycling.

The benefits of hydraulic press machines are numerous. They offer a high level of precision, essential for tasks requiring detailed work. Additionally, hydraulic presses are known for their durability and ability to handle large-scale production without significant wear and tear. Their ability to produce consistent results makes them a valuable asset in any industrial setting.

Safety Considerations and Guidelines

Operating hydraulic press machines requires adherence to strict safety guidelines to prevent accidents and ensure the safety of operators. Key safety measures include:

- Regular training for operators to ensure they understand the machine’s functions and safety protocols.

- Installation of safety guards to protect against accidental contact with moving parts.

- Routine maintenance checks to identify and rectify any potential issues before they lead to accidents.

- Use of proper personal protective equipment (PPE) such as gloves and safety goggles.

Understanding the machine’s emergency stop mechanisms and having clear communication protocols in place can further enhance safety. By prioritizing safety, businesses can minimize risks and create a safer working environment.

Maintenance and Troubleshooting

Regular maintenance is crucial for the optimal performance of hydraulic press machines. A well-maintained machine not only operates efficiently but also has a longer lifespan. Maintenance tasks include checking and replacing hydraulic fluids, inspecting seals and hoses for leaks, and ensuring that the pump and motor are functioning correctly.

Troubleshooting common issues such as leaks, unusual noises, or decreased performance can prevent minor problems from escalating into major repairs. Keeping a detailed maintenance log can help track the machine’s condition and identify patterns that may indicate underlying issues.

By investing in regular maintenance and being proactive in troubleshooting, operators can ensure that hydraulic press machines remain reliable and efficient, supporting continuous production and minimizing downtime.